Alberta Toll Free: 1.800.461.3812

Edmonton Head Office

8703 50 St NW

Edmonton, AB • T6B 1E7

p 780.465.8011 • f 780.465.8919

Calgary Office

#2 12180 - 44 St. SE

Calgary, Alberta T2Z 4A2

p 403.279.7958 • f 587.352.9745

Aqua Air Energy Solutions

1090 Homer St.

Suite 332

Vancouver, BC V6B 2W9

Nortek Air Solutions offers the innovation and expertise of the largest group of custom heating, ventilation, and air conditioning (HVAC) brands in North America for your commercial, industrial, or institutional indoor environment. Nortek Air Solutions products are custom engineered to bring you the optimal solutions for maximizing energy efficiency, reducing annual operating costs, improving indoor air quality, and achieving low sound levels. We offer high quality systems in multiple shapes, sizes, and configurations for new construction and renovation or retrofit applications.

Nortek Air Solutions custom-engineers a wide array of innovative products. You, our customers, are our top priority, so all of our products are engineered with you and your specific needs in mind. For years, our brands have been engineering the best possible solutions to your challenging installations. We build our products with an emphasis on the critical factors in HVAC today, with a commitment to quality and innovation:

- Energy efficiency

- Low maintenance

- Reliability

- Low sound levels

- Ease of installation

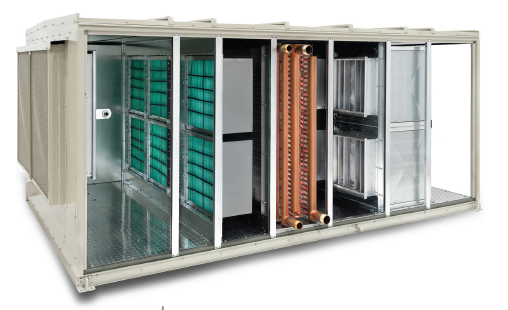

Nortek Air Solutions custom air handling solutions minimize total cost of ownership while meeting the most challenging requirements for size, efficiency and reliability. All our air handlers are available with the innovative FANWALL TECHNOLOGY® for enhanced air flow performance and redundancy in fan arrays.

Semi Customer Qx Air Handlers

500 to 24,000 cfm

indoor and outdoor applications

The Temtrol brand Qx air handler is ideal for applications with low CFM requirements and mid to high static pressures (leakage rates are less than 1% at 8 W.C.). Its compact size makes it a great choice for above-ceiling installations and for locations with ingress constraints. It is also ideal for meeting low CFM requirements on large projects where multiple custom Temtrol air handlers are employed to condition the space. Exterior configurations are available with a standard, center-pitched roof.

Rugged ITF Frame offers complete flexibility in unit arrangements, with a complete, welded internal steel base. A true "double bottom" construction with closed-cell sprayed foam in the base structure ensures airtight and watertight performance.

Air-Tight Unit Casing consists of 2-inch, double-wall, die-formed panels filled with fiberglass (R8.5) or foam-injected polyurethane (R13) insulation with a thermal break as standard. Closed-cell neoprene gaskets are used around the entire periphery with1/4-inch gasketed fasteners to yield airtight performance.

AHRI CertifiedT Coils are available in 1/2-inch and 5/8-inch tube OD sizes and tested to AHRI Standard 410 certification.

Quiet, Energy Efficient operation with available FANWALL® system features for air handlers which can result in reduced energy costs.

Custom HVAC solutions for demanding applications

For 75 years the Governair brand has been an industry leader in highly-customizable commercial and industrial air handlers. Governair's philosophy of delivering elite custom quality without the preventative costs generally associated with custom services results in industry leading value for markets of every scale.

Governair's product line is only limited by the designer's imagination. If you can imagine it, we can design and build it. From the simplest units to the most complex systems, our units are specifically designed to meet the exact needs of each project. Our team of highly skilled engineers and craftsmen has built a reputation for their ability to repeatedly provide solutions for the industry's most demanding applications.

Custom Packaged DX

- UltralineTM systems

- Designed to meet your specific performance and service requirements

- Fabricated, tested, and commissioned (optional) at our factory

- Delivered to your jobsite complete or in shipping sections that can be lifted into place using a crane and connected to electrical, plumbing or other utility service

- Ready for commissioning and start-up

Units are ideal for new construction or retrofit applications. You save on design time, installation labor, the coordination of trades and valuable, revenue-generating indoor space.

For more information on how we can design a custom solution for you, please contact your local representative

Vertical Self-contained Systems

- V-CubeTM (9 to 180 tons)

- V-Cube SlimTM (15 to 70 tons)

Benefits of vertical self-contained systems include:

- Floor-by-floor approach gives tenants more individual control over comfort conditions and utility costs for their space

- Units are designed for exceptionally quiet operation because they reside near occupied spaces

- Multiple compressors in each unit provide redundancy and allow efficient turndown in VAV applications

- Flexible configurations, including chilled water, DX, and water source heat pump, allow you to meet your application requirements with the most efficient system

- Eliminates need for a central chilled water plant and is significantly easier to service

- Energy saving waterside or airside economizer capability

- Knock-down capability allows units to fit through 3-foot doors without breaking refrigerant lines

- Units can be installed as floors become occupied to spread out equipment investment

For more information on how we can design a custom solution for you, please contact your local representative

Custom Air Handlers

Ventrol custom air handlers are designed for your specific needs for new construction, renovation and retrofit, and repair projects. We offer a broad range of options with units up to 300,000+ cfm. Ventrol has multiple innovative solutions for maximizing energy efficiency, reducing annual operating costs, improving indoor air quality, and achieving low sound levels. We offer knock-down construction, thermal break technologies, energy recovery technologies, FANWALL TECHNOLOGY®, and many other high quality custom air handling systems in various shapes, sizes, and configurations.

Thermal break technology - Ventrol's thermal break options minimize or prevent any condensation and frosting on the warm side of the panel caused by thermal bridging. Foam, fiberglass, or a combination of these insulations, is used along with a no-through metal design option to maximize thermal resistance between the interior and exterior of the cabinet.

Knock-down construction - We recognize not every project has easy access- particularly renovation and retrofit applications of older air handlers that are reaching the end of their useful life. Our knock-down construction option can provide the most cost-effective solution by avoiding the time and expense of a major tear-out and reconstruction project. In addition, the performance of your new system can be re-aligned to match current capacity and airflow requirements-with advanced technologies such as FANWALL TECHNOLOGY-to reduce operating expenses over the life of your new air handler.

Energy recovery ventilation - Ventrol's custom air handlers with energy recovery technologies are comprised of two counter-flow air tunnels with a common air-to-air heat exchanger transferring heat only, or heat and moisture, between the airstreams. Air-to-air heat exchangers carry the AHRI 1060 seal for AHRI CertifiedT performance for either wheel, plate or heat pipe heat exchangers. Integrating energy recovery technologies into the air handler design helps to capture the energy in the airstream, that would otherwise be exhausted to the atmosphere, and uses it to either pre-heat or pre-cool the outdoor airstream depending on the season. This pre-heating or pre-cooling can lead to significant energy savings and a reduction in the building's central plant size.

FANWALL TECHNOLOGY - Reengineering how you move air: compact, energy efficient, and with low sound levels. Breaks down large fans systems into smaller, more manageable fan arrays for added reliability and improved airflow efficiency. FANWALL TECHNOLOGY is ideal for new construction and retrofit applications.

Sound level reduction - Achieve sound levels never thought possible from an air handler with Ventrol's quiet design options. When faced with placing units near occupied spaces or sound sensitive applications, consider a unit equipped with a FANWALL® array and/or sound attenuators to meet your specific sound requirements. Ventrol continues to improve the sound performance of its equipment through use of Nortek Air Solutions's AMCA accredited sound and thermal-testing laboratory, and can offer customers the option of receiving certified sound performance reports.

All the flexibility you need for your HVAC project.

Whether your need is a unique unit configuration, special material of construction, flexibility in installation or demanding performance, Ventrol's engineers have the experience and know-how to design a solution for you. Flexibility and value are what bring customers back to Ventrol.

Custom Air Handlers

Since 1993, Huntair's innovative, custom air handler solutions and FANWALL TECHNOLOGY® have reengineered how we move air. Huntair specializes in HVAC systems used in mission-critical applications, including semiconductor, biotechnology and pharmaceuticals manufacturing, data centers, aerospace, hospitals, and extremely sensitive applications including cleanrooms.

All HUNTAIR air handlers are custom and built to deliver the performance you need for your unique application - providing exceptional value while giving designers the ultimate in flexibility when solving any HVAC design problem.

The ability to provide unique, custom solutions that are simply unachievable using commercial cataloged products differentiates Huntair in air handler replacement and upgrade opportunities. For example, many air handlers installed in the 90's or earlier are near the end of their expected life. The added maintenance to keep them running - or the ticking time bomb of a catastrophic failure - are compelling reasons to replace or upgrade these air handlers. But because they are often tucked away in the bowels of buildings with severe egress constraints, the prospect of a replacement is daunting. In many cases, significant destruction and reconstruction would be required just to remove the old air handler and bring in a like-for-like replacement. In addition to being cost-prohibitive, this approach could cause an unacceptable interruption in your building's operations.

Huntair offers complete solutions to match even the most difficult of your requirements for air handler replacements and upgrades.

Complete Air Handler Replacements

For complete air handler replacements Huntair offers several alternatives depending on the project:

- Modular air handlers are typically delivered in sections that are then assembled on site.

- Knock-down air handlers are first assembled in the manufacturing plant and then disassembled into individual components that are sized to meet the access requirements of the project.

- In cases where space constraints are extremely tight, built-in-place air handlers can be the most ideal solution. 3D modeling of the space allows components to be pre-built to minimize field changes that affect installed cost and timeline.